Recently, entrusted by the Jiangsu Provincial Department of Science and Technology, the Nantong Municipal Bureau of Science and Technology organized the acceptance of the Jiangsu Provincial Carbon Peak Carbon Neutralization Science and Technology Innovation Special Fund project "Research and Development and Industrialization of Pyrolysis Technology and Equipment for Green and Clean Utilization of Low-Rank Coal" undertaken by Jiangsu Pengfei Group Co., Ltd. After reviewing each item, the acceptance committee concluded that the project had completed all the indicators stipulated in the contract and agreed to pass the acceptance.

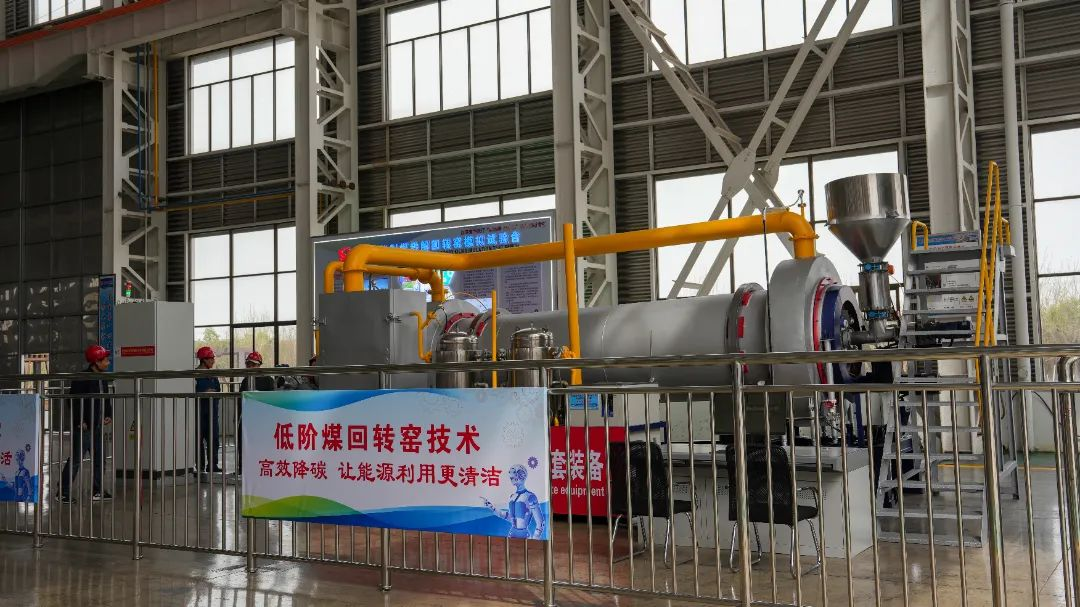

This project, in collaboration with Tsinghua University, completed the research and development of integrated drying and pyrolysis upgrading technology for low-rank coal and complete sets of rotary kiln equipment. It overcame key technical challenges such as the manufacturing of key components for large-scale pyrolysis rotary kilns and the control of sliding rate difference of involute gear pairs. It has achieved the industrialization and market application of complete sets of (100-600) ton/hour pyrolysis rotary kiln equipment with independent intellectual property rights, filling a domestic gap.

The equipment integrates a drying and pyrolysis system, a high-temperature flue gas recycling system, and an intelligent monitoring system. It is used to pyrolyze low-rank coal into high-quality upgraded coal, light tar, and high-calorific-value coal gas, and to control and reduce the emissions of pollutants such as NOx, SO2, and dust generated from the combustion of low-rank coal by more than 20% from the "source".

The project has been granted 24 patents, including 8 invention patents and 16 utility model patents. It developed a circulating heat transfer process based on high-temperature coal gas and high-temperature pyrolysis coke; developed intelligent temperature monitoring and feedback technology within the kiln; and built an online oxygen concentration monitoring and analysis device. Combining computer-aided design and matching control with displacement coefficient matching control technology during processing, the gear design is scientific and intelligent, improving processing accuracy and service life. The project's industrialization has accelerated my country's green and low-carbon energy transformation and industry carbon peaking, constructing a clean, inefficient, safe, and efficient energy system, and injecting strong momentum into the sustainable development of my country's energy industry.

The successful acceptance of the "Research and Industrialization of Pyrolysis Technology and Equipment for Green and Clean Utilization of Low-Rank Coal" project marks a solid step forward for Pengfei in its green and low-carbon energy transformation and industry carbon peaking efforts. During the project's development, Pengfei, through continuous technological innovation and R&D investment, assembled a high-caliber R&D team, overcame a series of technical challenges, and achieved efficient, stable, and environmentally friendly operation of the pyrolysis equipment. Simultaneously, Pengfei Group actively collaborated with experts and scholars in related fields both domestically and internationally, continuously absorbing and learning from advanced technologies and experiences, laying a solid foundation for the project's successful acceptance. Pengfei Group will actively respond to the national carbon peaking and carbon neutrality goals, promoting digital transformation and green development. It will further strengthen the application of digital and intelligent technologies in its industries to improve production efficiency and energy conservation and environmental protection levels. At the same time, the company will actively explore green and low-carbon development paths to contribute to sustainable development.